Most energy efficient

1. Real matrix control and high standard insulation make Yuntong heating furnace the most power saving one. The heating energy efficiency is well above 90%.

2. Pass-through quench with its newest design can considerable reduce quenching power cost.

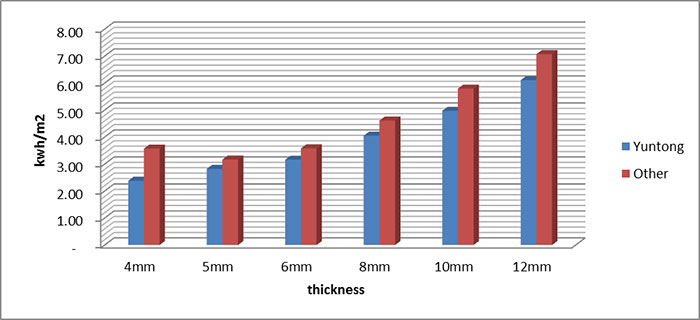

Chart 1. Comparison of power consumption between Yuntong and most other brands.

Much lower peak demand

1. Pass-through quench can minimize the blower installed power while reducing the high power run time. This makes it possible to offset the peak demand of heating furnace and quenching fans.

2. Optimization in heating and quenching power control can reduce the peak power without affecting the production rate.

3. Lower peak demand means customer can run same production on smaller power supply, or run more production on same power supply.

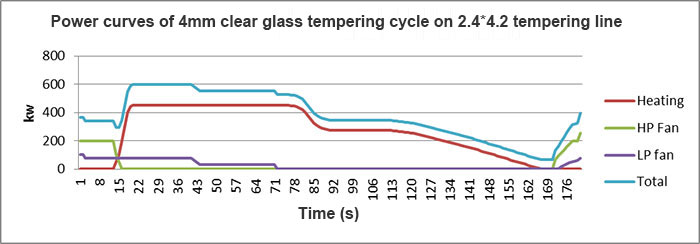

Chart 2. Power demand: 4mm tempering cycle on a 2.4m x 4.2m tempering line.

The chart shows the cycle time is 180 second equals 20 batches/hour. The total peak demand is only 600kw, which is the lowest among different brands of the same size machine.

Very powerful forced convection heating system

1. Yuntong lately optimized the forced convection design and improved the efficiency by over 5 times. The hot air streams are more concentrated, and the air has more space to return to fan inlets.

2. In Yuntong forced convection design, air is blown out and return at the same zone. There is no turbulent air current therefore both the heating control and forced convection control can be better targeted.

3. Cassette type forced convection nozzles: much smaller nozzles does not accumulate distortion therefore the whole system is much more reliable than big-box nozzles.

4. Self-cooled fan driving system does not need back up power nor any diesel generator.

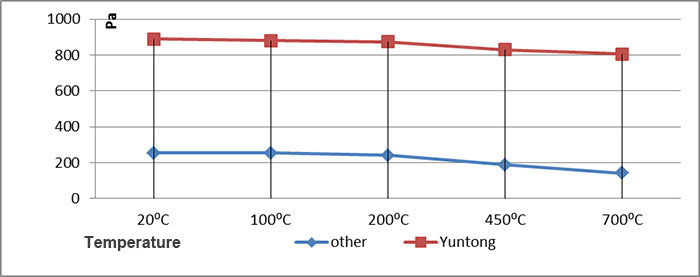

Chart 3. Comparison of air stream pressure at 120mm from the nozzle.

FC power density = 2.63kw/M2

The chart shows the comparison between different type of hot air circulation type of forced convection system. Yuntong new design is 3.8 to 4.5 times as other types. When measuring this, the blue line has FC power of near 3.5kwh/m2

PID Quenching Pressure Control

1. The control system can adjust fans and valves to quickly reach the set air pressure and maintain constantly.

2. The control system can adjust the pressure in response to ambience temperature.

3. Glass can always be quenched and cooled at the same strength so the quality can be consistent. Customers do not need to break glass from time to time to check fragment.

4. Other manufacturers normally simulate the pressure by adjusting fan speed and valve angle, but does not sense the real pressure. But air pressure may get interfered by external factors such as wind, inlet block, valve malfunctioning etc. So customers often have to break glass from time to time to check fragment size.

No-flaw chiller

1. Setting the goal to produce tempered glass with zero quenching anisotropy, Yuntong developed new chiller design and made big success in early 2016. Many pieces of tempered glass being stacked together, quenching flaw is invisible.

2. The new chiller design can further reduce power consumtion by approx. 8% in the pass-through section.

Linked V-Belt for furnace and chiller conveyers.

1. In contrast to PU ring which is commonly used in conveyer drive, linked V belt is more stable and does not stretch in length. The working life is much longer, and changing it is much easier. There is no need to unbolt the whole shaft. The long term maintenance cost is very low.

2. Like PU ring or steel belt, linked V belt allows slipage of any individual rollers under certain force. There is no risk of Kevlar cutting or ceramic roll breakage in case of glass breakage.