- Home

- Discontinued Products

-

- Gas Heating Glass Tempering FurnaceAs natural gas allows the glass sheets to be evenly heated at a lower temperature (670℃~690℃), the heating rate is improved, and the period for the glass staying on the roller is shortened. This enables the glass tempering furnace to minimize the chances of glass deformation, and improve the production rate and glass quality.

- Tank Furnace Equipment for Float Glass Production Line

- Glass Tank FurnaceMade of steel structures and refractories, the glass tank furnace includes L shaped suspended wall, melter, neck, cooling end, runner, combustion system, waste discharge system, wind cooling system, and etc. The tank furnace offers advanced performance in terms of melting rate, heat consumption, and service life compared to like products in the field.

-

- Batch Feeding Machine/Batch Charger (Feeder)For the batch feeding machine, the commonly used are large leaning blanket batch charger and arc blanket batch feeder. They are used for continuous feeding of thin-layer batch.

The feeding machine charges the batch, at a required rate and in a required shape, into a tank furnace.

- Combustion Air, Air Cooling SystemThe combustion air system provides sufficient combustion air to aid in fuel burning.

The air cooling system acts as an air source offering adequate pressure for tank furnace cooling. It helps ensure safe running of the melting furnace.

- Tin Bath Equipment for Float Glass Production Line

- Tin BathThe tin bath is made up of steel structures, refractory structures, heating elements, cooling system, shielding gas system and control system. It is suitable for forming glass with thickness range of 2-19mm. The tin bath makes high quality products which are conforming to national standards of China. The forming process is automatically controlled.

-

- Knurl MachineThere are many types of knurl machines such as suspending type, stand type, semi-automatic, full-automatic, and more. Fitted on both sides of a tin bath, knurl machines play an important role in improving glass quality, glass production rate, and thick or thin glass making.

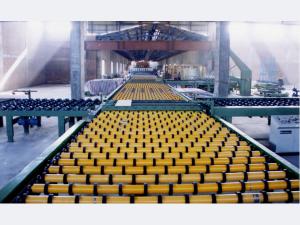

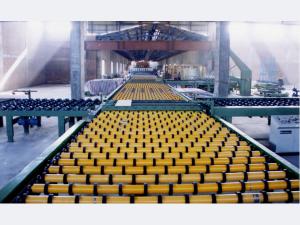

- Annealing Lehr for Float Glass Production Line

-

- Full Set of Annealing Lehr EquipmentWith heat insulation, the annealing equipment is transversely divided into zones for heating and cooling. This can effectively control the cooling speed and crosswise temperature difference of the glass ribbon. According to the requirements in terms of glass output, specifications and thickness ...

-

- Roller for Annealing LehrThe roller for annealing lehr is supported by suspended bearing. Its transmission shaft is driven by motor with stepless speed regulation. The screw gear fixed at the ends of driving shaft and roller shaft offers auxiliary driving.

Conveying rollers with different diameters, spacing, and materials are used according to different temperatures ...

- Annealing Lehr Drive and Transmission SystemThe roller table uses suspended installation. Two variable frequency AC motor drive systems are used, with each one acting as a backup for the other. The drive system provides stable speed, and a wide speed range.

- Air Pipe Cooling SystemAccording to the technical requirements for different zones, the annealing lehr uses different cooling methods, pipelines and air supply systems. The air pipe cooling system offers the advantage of reliable performance and easy adjustment.

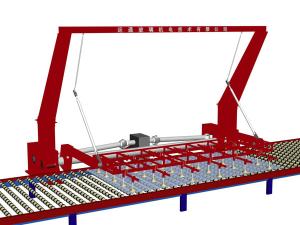

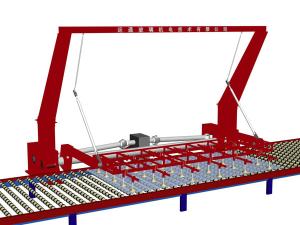

- Cold End Equipment for Float Glass Production Line

-

- Glass Cross Cutting MachineIt can set the positions for cutter lifting and lowering by means of the signals it receives from a glass longitudinal cutting machine.

In addition to sending signals on glass breaking, the glass cutting machine can provide not only synchronous ...

It can set the positions for knife lifting and lowering by means of the signals it receives ...

-

- Glass Longitudinal Cutting MachineThere is a screw driven by servo motor and five cutting tools on either side of the bridge of the glass longitudinal cutting machine. While the cutters on one side are cutting, the cutters on the other side will conduct tracking based on signals from the control systems. The cutters on one side act as hot backup for those on the other side.

-

- Cross Snapping DeviceThe cross snapping device uses a Φ150 rubber roller as the main roller for snapping, with the max. stroke of 50mm. The following roller is driven by an air cylinder. In case of producing thin glass, adjust the screw handle to lift the main snapping roller a little higher than the upper surface of the roller table.

-

- Accelerating Separation RollerAlso, the accelerating separation roller is capable of grouping and delivering the glass panes that are cut into measured sizes and arranged with a certain distance between them. This allows sufficient time for the subsequent procedure in thin glass or short plate production.

-

- Glass Severing Machine and RollerThe snapping roller is equipped with a glass severing machine for double snapping. The roller offers automatic speed control within 150-1800 m/h. The edge-snapping wheels conduct tracking of the glass movement automatically or manually. The width of roller table can be adjusted automatically according to the glass width.

-

- Glass Conveying RollerOur glass conveying roller is continuously updated and optimized over the years, offering bevel gearbox drive, chain drive, and other types. In order to meet different requirements for producing glass of all thicknesses and types, the roller can be designed with three-support, four-support, bilateral transmission construction, or others.

-

- Longitudinal Snapping and Separation DeviceThe longitudinal snapping and separation device separates the glass ribbon longitudinally into several ribbons, which facilitate cutting them into glass panes of certain sizes.

-

- Glass Dropping DeviceThe glass dropping device is composed of a dropping roller, receiving roller and crusher. It includes emergency dropping, main line roller dropping, and dropping for snapping. The sizes of the crushed pieces of glass do not exceed 50mm×50mm.

-

- Glass Distribution MachineThe glass distribution machine is suitable for glass with thickness of 2-19 mm. It can not only distribute glass plates continuously in one direction, but also distribute alternately on the left and right side. The distribution system makes it possible for delivering through multi channels and stacking at multi exits.

-

- Glass StackerThe glass stacker is a kind of equipment which utilizes a vacuum device to vertically grip the glass plates. It consists of an angle turning device, glass distribution machine, alignment apparatus, roller for glass gripping, glass stacking machine and piling car as well as vacuum generator.

The glass stacker is a kind of equipment which utilizes a vacuum device to vertically grip the glass plates. It consists of an angle turning ...

- Float Glass PackagingThe float glass packaging device works on the principle of static electricity. It sprays fine powder of mild acid organic materials onto the glass surface evenly, which forms a kind of padding between glass plates. The float glass packaging not only can be used as a substitute for wrapper, but also protect the glass from going moldy.